Want to read in Dutch? Click here

Sustainability, it’s a theme I’ve written about before. With more and more companies embracing sustainability, it’s no surprise that this is a hot topic. Yet sustainability remains a grey area. How can you be sure that the clothes you are wearing are recycled? And how sustainable is sustainable? We have been grasping in the dark for a long time, but there is now a standard being developed that will show you exactly how sustainable (company) clothing is.

I spoke with Shirley Schijvens, owner of Schijvens Corporate Fashion. Shirley is involved in the project and already uses a system that makes her clothing traceable. The system allows you to know exactly where your clothes come from. Very interesting! Time to dig deeper…

Shirley, the first thing I’m curious about is where the standard is at. Why and how badly is a standard needed?

“It is very important that there is a guideline for circular textiles. Because nowadays many companies claim to be circular, but it means something different for everyone. For example, one company might take their clothing back while another upcycles. Also, the chance of greenwashing, pretending to produce circular clothing, is high.

That is why we are now working on an NTA, Nederlands Technische Afspraak (Dutch Technical Agreement). This is being done in collaboration with companies, the trade association, and the NEN. As soon as this standard is available, all companies that claim to make circular textiles will have to comply with it. We are currently working together with the NEN on a Dutch standard, but in the future I expect this to be implemented at a European level and become an ISO standard.”

Can you explain what requirements companies must meet to qualify for this standard?

“Because not every company makes 100% circular textiles, there are different levels. Roughly four levels. First, you have the level of reuse. This means that garments that have been worn but are not yet threadbare and can be worn again. Think, for example, of employees who leave a company and hand in their work clothes. They can easily pass these on to another employee.

Second, as a company, you can choose to repair clothing. We hear little about this, but it is a very simple way to extend the life of clothing. A small hole or a broken zipper does not mean that a piece has to be discarded. At Schijvens we have an in-house workshop where we do repairs. The only drawback with repairs is we have a shortage of people in the Netherlands who are skilled at this. Fortunately, I have an employee from Somalia who had a sewing factory back home and is happy to continue his profession here. We have already repaired over 20,000 items of clothing in our workshop.

The third level is re-manufacturing. It is important that old clothes are not thrown away but reused. We can make these into something completely different, think of bags or other accessories.

And finally, there is the level of recycling. Old clothes being used to make new clothes. Depending on the fabric, you sometimes have to add extra raw materials. With clothing made of 100% polyester, you can easily make a new shirt from an old one. Whereas with cotton, you need to add other raw materials, but these can also be waste such as PET bottles.”

And where is Schijvens at with these levels?

”When it comes to circular textiles, we have been at the highest level for years. We recycle our clothing and use as much waste as possible for additional raw materials. In addition, we are affiliated with the Fair Wear Foundation and are one of the highest-scoring companies on the list. Besides circularity, proper working conditions for the people who work in the factories are of utmost importance for us.

But it doesn’t stop there. We are always looking to see how we can make clothing even more sustainable. For example, we have a workwear line called T’riffic. We started with a Fair Wear collection where all the garments are produced under good working conditions. We pay attention to matters such as a living wage instead of a minimum wage and minimizing overtime.

Two years ago, we started T’riffic Circular, our second clothing line. These clothes are not only made under good working conditions, but we also use 100% recycled materials. That’s where we ultimately want to go; only clothing made from recycled materials. To realize this, we also take all our clothes back. From our two T’riffic lines, and the clothes that we custom develop for companies such as Albert Heijn, Intratuin, Kruidvat and CSU.”

– The interview continues below the photos –

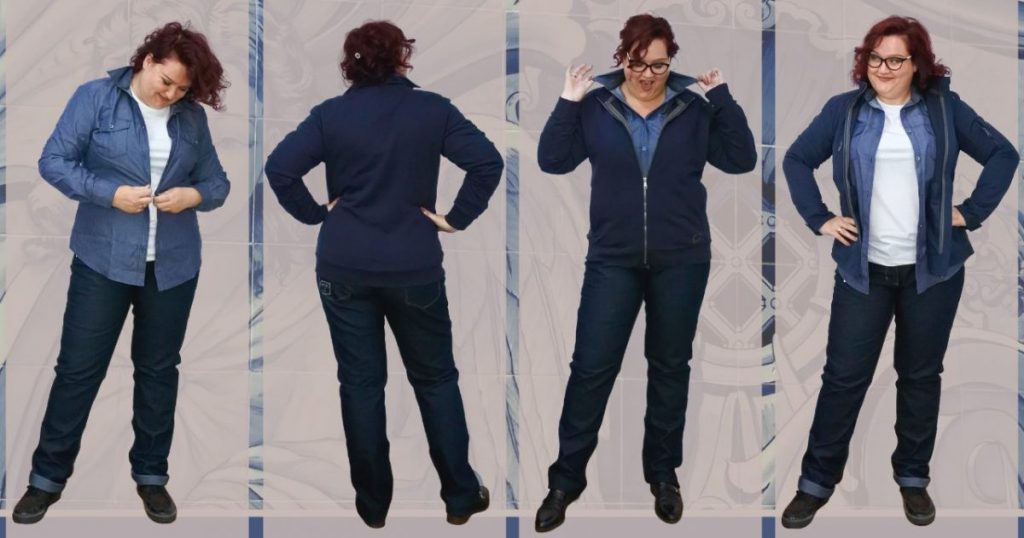

To give you an idea of the T’riffic clothing line, I have added some photos with items from the collection. The jeans are from the Fair Wear line and the rest is from the T’riffic Circular line. We make all the tops from 100% recycled materials. The garments are fairly basic and can therefore be worn in different ways, casual with work shoes or for a smarter look with braces and dressy shoes. For companies, the tops can easily be personalized with logos either printed or embroidered on them.

You’ve been at this for a long time. How can people know for sure that companies adhere to the standard?

“Of course it is important that it is not just a catchy story. It must also be provable and that is not so easy at the moment. Saxion University is now looking into whether the fabrics can be examined in a laboratory to see if they have been recycled. They’ve made a lot of progress and expect the technique to be ready this year.

We currently use Aware. With this system, you add a special powder to the fibers used to make textiles. We can add it to old textiles and waste which we use to in our clothing production, making the textiles traceable. This is very important because the yarn manufacturing, the weaving of the fabric, and the assembling of the clothing take place in different countries and for this reason, it is difficult to have an overview.

As soon as we receive our clothing, we use a special scanner to see whether the powder has been incorporated into the fabric. Because the fabric is scanned at every step, we can ultimately follow the entire process. This way we can track our materials and it is also not possible to add other materials in. All this data is stored in a blockchain (a reliable and up-to-date register) and the manufacturing factories cannot change it.”

Do you expect a system like Aware to become popular in the future?

“In the future, producers of, among other things, circular workwear will have to show their working method. At least, if they want to meet the standard. So a system such as Aware is a very useful tool. At the moment, we are the only one in the Dutch company clothing market using this.

I hope in the future that fashion companies will also join. And that the government sets up a transparent system communicating with the consumer.”

That sounds fantastic! This makes it easier for both companies and consumers to purchase sustainable clothing. Is it possible to buy your clothes as a consumer?

“Certainly! Our clothing is available to everyone. Companies can contact one of our dealers. Consumers or self-employed people can also order some items via Proforto.”

I wrote this article in collaboration with Schijvens Corporate Fashion. Please read my (Dutch) disclaimer for more information.

Nice post! If you are looking for some trendy and cool eco-friendly jeans, then FARAH NAZ New York is a place to go. They provide amazing online services and their products will definitely leave you satisfied. Check their website out!

Great Article! Thanks for sharing it. If you would like to get a discount on your clothing you can check out SavingSays.com where you can find thousands of coupons and discounts. Keep doing the good work.

With custom clothes, you can rest assure that your clothes will always fit and hang just right – making you look near perfect.

Now-a-days sustainable method is growing well. you may find the jobs by visiting

garments jobs